What is electroplating?

Electroplating, commonly referred to as electrodeposition, is the process of depositing a layer of metal onto an existing metal object for the purpose of changing the surface characteristics. It is performed using a plating solution that contains real precious metal particles that bond and deposit onto the surface of the item which is being plated.

Reasons for electroplating a surface might include - providing weather-proofing or protection against corrosion, strengthening a surface to stand up to more wear and tear, or improving the appearance of a surface to make it more appealing.

To give an example of functional electroplating - metal plating is widely used in dentistry in a whole host of applications such as protecting dental devices and tools from corrosion. Plating with antimicrobial metals is the most sterile choice for dental equipment and offers the best protection against infections when performing dental procedures. Electroplating is even used in the process of creating dental implants, crowns, and bridges due to the durability of the metals used.

A variety of finishes that are commonly used for aesthetic purposes include - 24k gold, silver, rhodium, rose gold, and platinum, whilst gold especially, is also used regularly for functional reasons. On the other hand, a metal such as zinc provides fantastic protection against rust on surfaces frequently exposed to the elements.

Electroplating is used on metal surfaces via two main routes. In this article, we will explore the main methods of application.

What is Brush Plating?

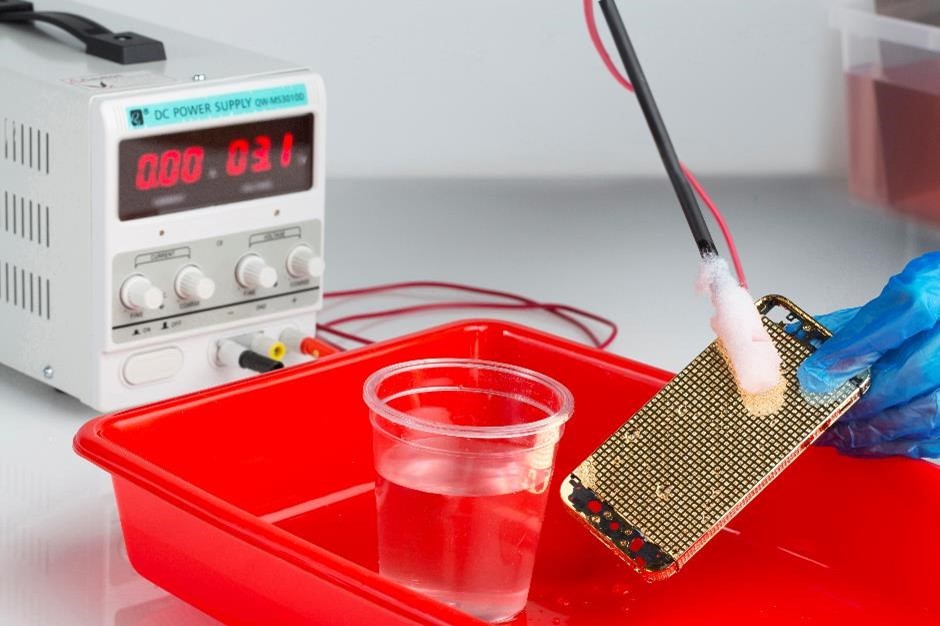

The brush plating method consists of effectively ‘painting’ your plating solution over an item using a plating probe that has been prepared with a swab, working on just one bit of the surface at a time.

Brush plating is the quickest method to set up, but plating can take longer, and care is needed to avoid imperfections in the plated surface. It is best to experiment with a few practice pieces before starting an important project.

What is Tank Plating?

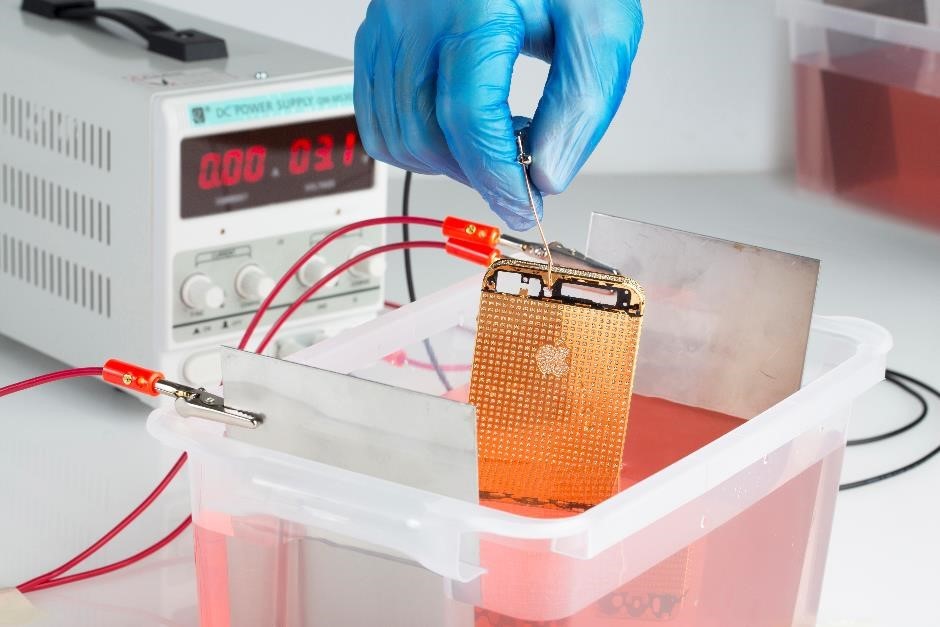

Tank plating is another popular method of electroplating. This method consists of submerging the entire metal item to be plated in an appropriately sized tank that has been prepared with metal anodes (sheets) and your chosen plating solution. The entire item is plated simultaneously as you lower the item into the solution, usually on a copper wire. Since there is no handling of the item, items come out more evenly plated in thickness and a flawless finish is easier to achieve.

To achieve a good result when tank plating, you must begin by working out the surface area of your item but there are many online surface area calculators which can be employed to make this task easier.

What is Pen Plating?

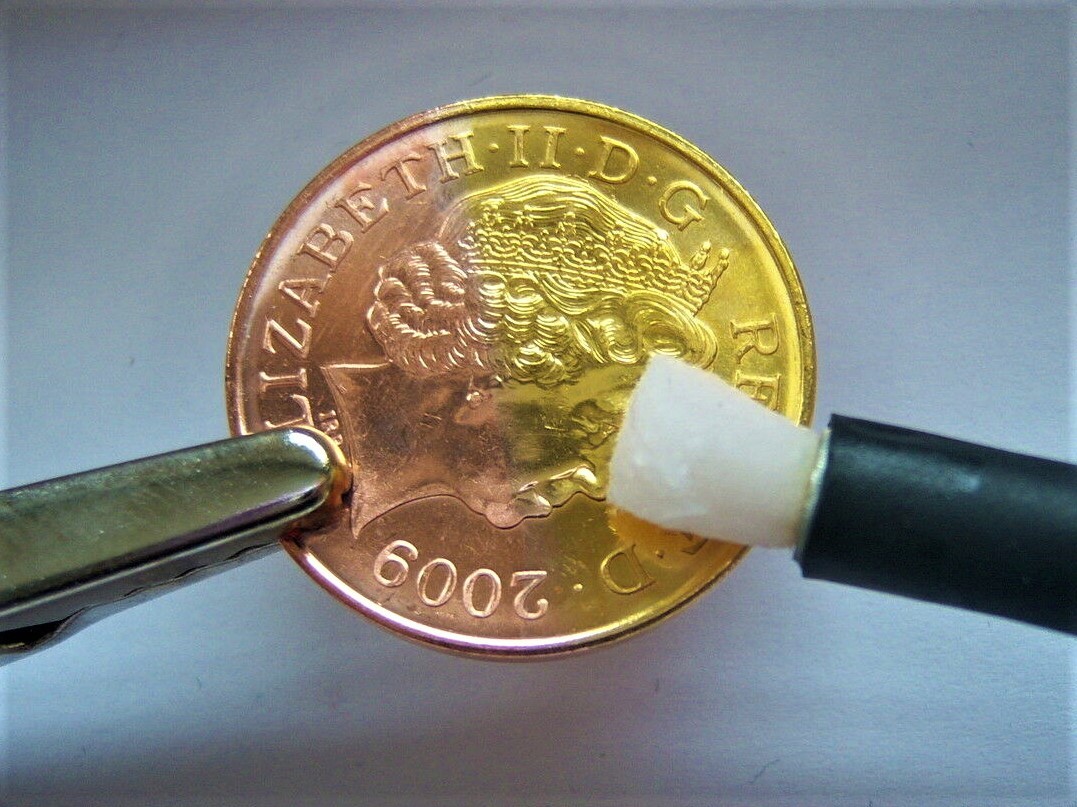

You may have heard of pen plating- this is a form of brush plating, only it works on a smaller scale. With this method, a plating probe is primed with a plating nib and this is used to ‘paint’ over the item much the same as when brush plating. Pen plating is popularly used for intricate and finely detailed items as the plating nib offers more control than using a swab.

Our 10A SmartAmp Plating Machine can do all of these processes and features in many of our electroplating kits.

Which electroplating method should I use?

As you can see, electroplating has lots of uses, both decorative and functional.

Electroplating is usually performed via tank plating when items are larger or to allow the plating of more items in one go. This method consists of a more expensive initial set-up but depending on the types of jobs that need to be completed, can often be the most time-saving and cost-effective method of plating overall. Results can be guaranteed to be of a high-quality without imperfections, as the whole item is submerged in plating solution, ensuring that every inch of the surface is plated smoothly and equally.

Brush plating allows you to be set up and ready to go quickly, but whilst it is more than possible to achieve results of the same quality produced by tank plating, care must be taken to ensure that all areas of a surface are brushed evenly to avoid imperfections. This method is ideal for small to medium-sized objects and platers with a smaller workload, as each item must be plated individually.

Pen plating is designed for use on smaller objects and is especially helpful when plating detailed areas as fine control can be exerted.

Whatever the reason for your endeavors in electroplating, we can supply you with all of the equipment needed to best suit your situation and achieve great results. Many of our kits provide the option for all of the above methods, allowing you to select the most appropriate method for each project that you do. Alternatively, if you are looking to buy a kit specifically designed for brush or pen plating, we also have you covered!

Why not visit our shop to take a look at the options?

Further reading

Check out our article The Great Plate Debate for more details on brush plating and tank plating.

If you would like to learn about plating non-conductive surfaces such as plastic or organic materials, please see our article: Electroforming - A Brief Guide.