What is electroforming?

Electroforming is the process of plating non-conductive (non-metal) surfaces such as plastics, organic items and ceramics to name but a few.

Electroplating and electroforming processes are commonly used in a variety of industries, these include electronics, manufacturing of medical instruments, machinery, decorating, crafts, jewellery, and the arts. Electroforming is also used in the field of dentistry to aid the creation of porcelain inlays and crowns.

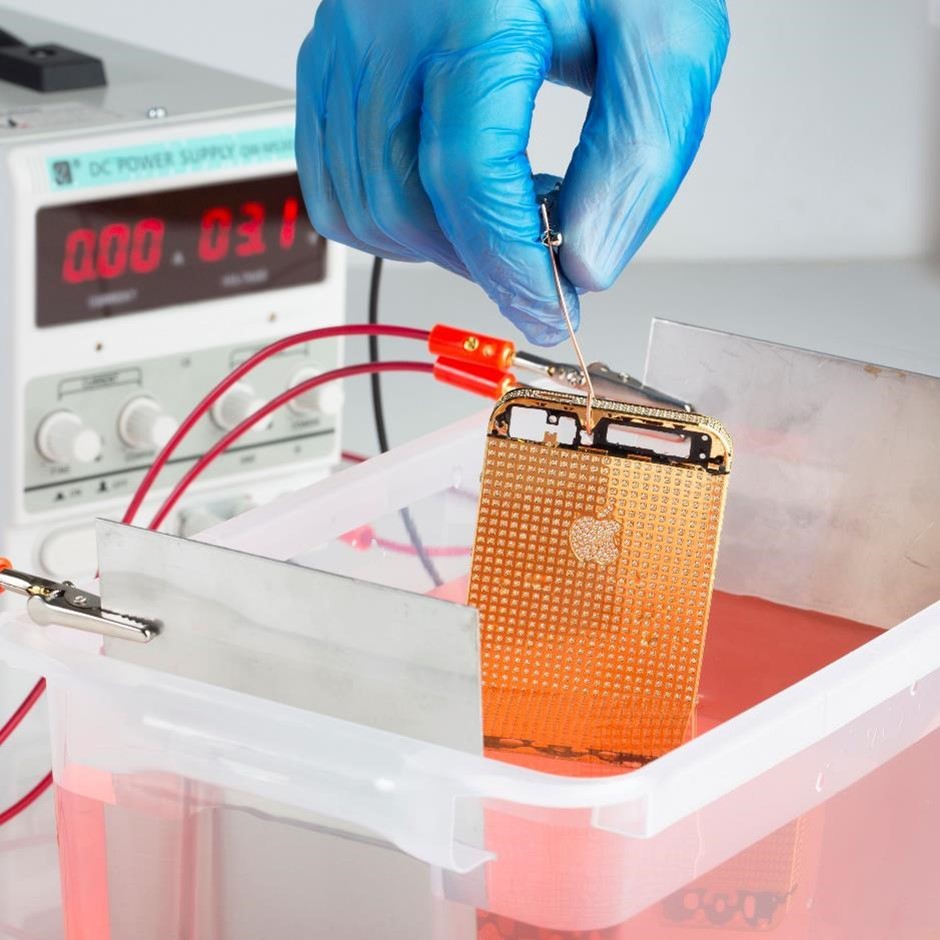

The electroforming process involves tank plating, and always involves our G.S.P Electroforming Copper Solution. This is a special type of copper solution that builds up very slowly (over a span of 3 to 6 hours or more).

The result is a rigid, copper-plated item that has a mirror shine with no polishing required. The copper makes the item conductive - a requirement for electroplating - therefore, after this stage, it is possible to electroplate the item in a multitude of precious metal finishes such as 24k gold, silver, platinum, rose gold, or rhodium. All this on an item that is not even conductive to start with!

How does electroforming work?

The non-conductive items are sprayed in a special conductive paint, dried, and lowered into the electroforming copper solution for several hours. The result is an item that is now covered in a mirror shiny copper, requires no polishing, and can be left as is or is perfectly ready for plating in other finishes.

Whilst items are plating in the tank for all this time, you do not need to keep monitoring them, the plating machine is able to keep the exact amount of current as it self-adjusts, meaning that you can get on with other things while the plating runs in the background.

Which kits can help me to achieve this?

There are several aspects at work when an item is being electroformed – our G.S.P Prodigy Range kits incorporate our Mirror-Tech System™ and contain all of the necessary equipment, anodes and various other accessories to do the job well. All elements of the Mirror-Tech System™ are important as they all have specific jobs to do. No single element will result in successful electroforming, they all work together to achieve consistent and shiny results, straight out the tank.

Our 10A SmartAmp Plating Machine, with integrated plating technology, is at the heart of these kits. Because of this, you can even combine the benefits of electroforming with general tank plating on metal, taking advantage of the ability of the our G.S.P Electroforming Copper to generate a shiny finish inside the tank. This will vastly improve the surface quality of items that were metal to begin with.

What are the other benefits of electroforming?

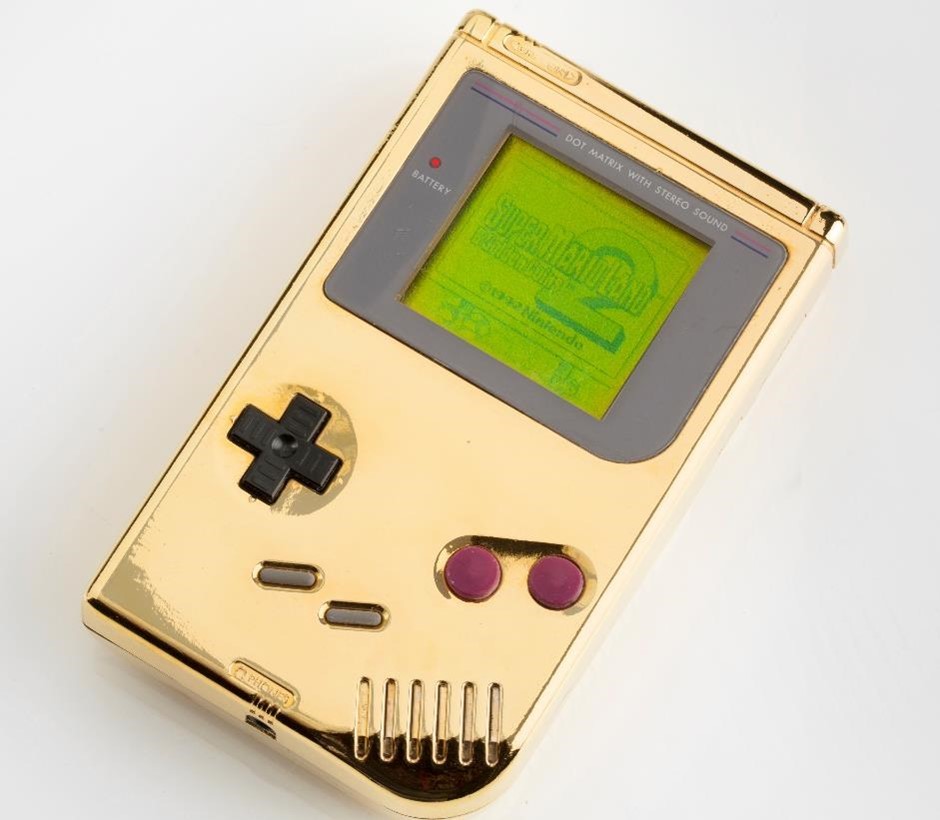

Many people use our electroforming kits to make light work of plating various metals such as brass, zinc and other old dull metals, to restore them to a brilliant smooth shiny finish before plating in gold or silver, or other finishes. This cuts out the entire buffing and polishing stage, and this is useful when it comes to items that cannot be easily buffed or where buffing risks damage.

Electroforming is a great way to create a real metal finish on items that are non-conductive, offering huge scope for creativity and experimentation.

Here is an example of another non-conductive item, this time something organic, that has been electroformed and gold plated.

This real rose was purchased from a florist and preserved and immortalised in real 24k gold using one of our G.S.P Prodigy Kits. As you can see, electroforming has allowed us to capture the finest of details on the delicate petals and stalk of the flower, and the finished result is a strong and rigid, solid object that will stand the test of time. The shiny gold finish was achieved by the tank plating process alone, with no polishing required at any stage.

Here we have a shell collected from the sunny Kent coast that we electroformed and plated in copper using our budget electroforming kit - the G.S.P Belle Fleur.

This kit is specifically designed for plating with the rawer aesthetic popular with bohemian style jewellery. Whilst the kit is capable of producing a shiny plated surface, it does not incorporate the Mirror-Tech System™ and produce the high-gloss sheen of the G.S.P Prodigy Range - but that is not its job!

The shiny image at the bottom shows the result straight after copper electroforming. Copper tarnishes quickly, so a lacquer would need to be applied if we wanted to keep the shine.

However, we decided to spray the shell with water to encourage oxidization. The result is shown in the top image. Oxidization brings an aged look which can also be achieved by applying a patina.

Plating organic items to turn into pieces of art, jewellery or ornaments is a common use for our electroforming kits.

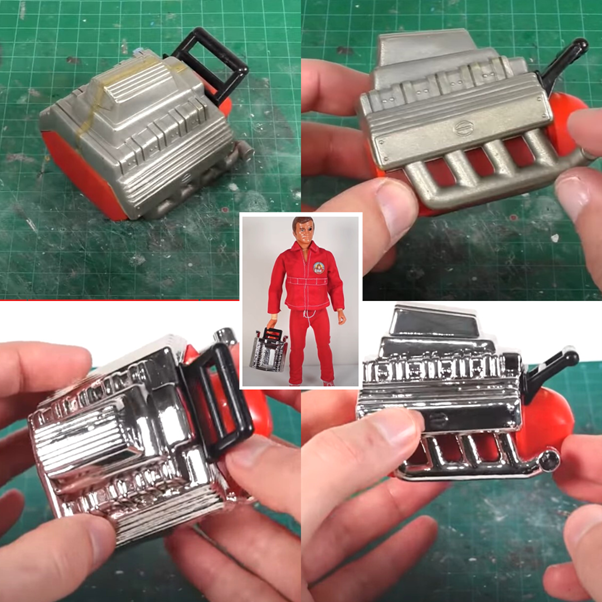

Here's an example of how we've used rhodium plating to get a super-shiny chrome-like finish.

Vintage toys fans may remember the Six Million Dollar Man Steve Austin doll - we collaborated with toy restorer Toy Polloi who wanted to bring an authentic metal look/feel to the plastic engine block and show the process on his YouTube channel.

We electroformed and rhodium plated the engine block, taking it from plastic to metal, bringing the chrome-like appearance of the prototype which was never released. Plating in real metal gave not only an authentic metal appearance but also added weight to the part, further adding to the appeal.

You may be wondering why we didn't chrome plate the plastic part - unfortunately, chrome plating solution has been identified as a chemical that may be unsafe for unregulated/home users and this is the reason we do not offer it for sale to our customers.

We wanted to show just how great plating in rhodium can look and how similar it is in appearance to chrome. We could also have used platinum plating solution to get a similar aesthetic.

Very cool project, if you'd like to watch the video of this vintage toy restoration, see the link below. Electroplating the engine block starts at minute 16:43 of the video: Six Million Dollar Man Restoration.

Can I select which areas of an object to plate?

Yes - it is perfectly possible to choose to plate one area and leave another un-plated!

This is achieved by masking off the section you've chosen not to plate - in our example, we've masked the blue stone but not the dragon's eyes. We could have easily reversed this by choosing to mask off the eyes and plate the stone, or plate all areas of the ornament - all personal choice.

This means that when electroforming jewellery with elements such as crystals, stones or other embellishments, you can decide exactly where you'd like plating to happen.

*Please note - masking off areas applies to the electroforming process for non-metals ONLY. If plating jewellery or other items made from metals e.g. silver, the specific chemicals involved in electroforming are not needed. This means that metal jewellery can be submerged in the plating solutions and any stones or other non-metal areas will remain unaffected by the solutions and will not plate.

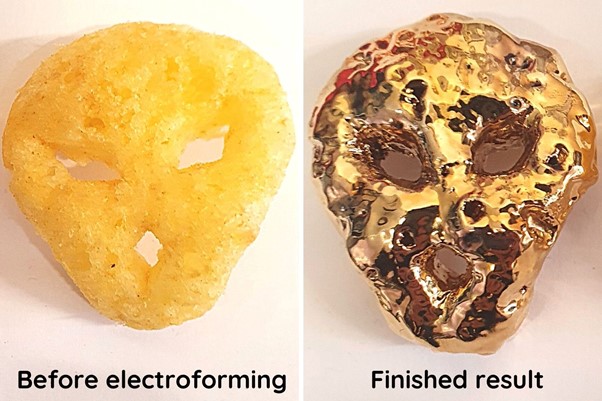

The electroforming kits that implement the Mirror-Tech System™ are capable of plating practically any object - here we have again used a kit from our G.S.P Prodigy Range to take a well-known corn snack and plate it in copper. The difference in the glossiness of the plated surface is striking when compared with the shell in the above photograph. The experiment went so well that we also decided to create an additional gold-plated version.

We have achieved a mirror-shiny finish and the objects are sturdy and rock-solid now that they are coated in real metal. We could have gone on to plate in a multitude of other finishes such as silver, rose gold, or even rhodium - we think these aliens would look very unique as necklace pendants!

Obviously, the electroforming of food items is not the usual mandate for our clients, but this experiment really shows the breadth of options and scope of what is possible with our kits.

The sky (or maybe space) really is the limit.

Further reading

Check out our article Electroplating v Electroforming for more information.

Explore our G.S.P Prodigy Range containing our most popular electroforming kits that plate to a mirror-shine, every time.

For electroforming small non-conductive pieces in copper, with an earthy aesthetic, please see the G.S.P Belle Fleur Electroforming Kit.